what is DrubitTM?

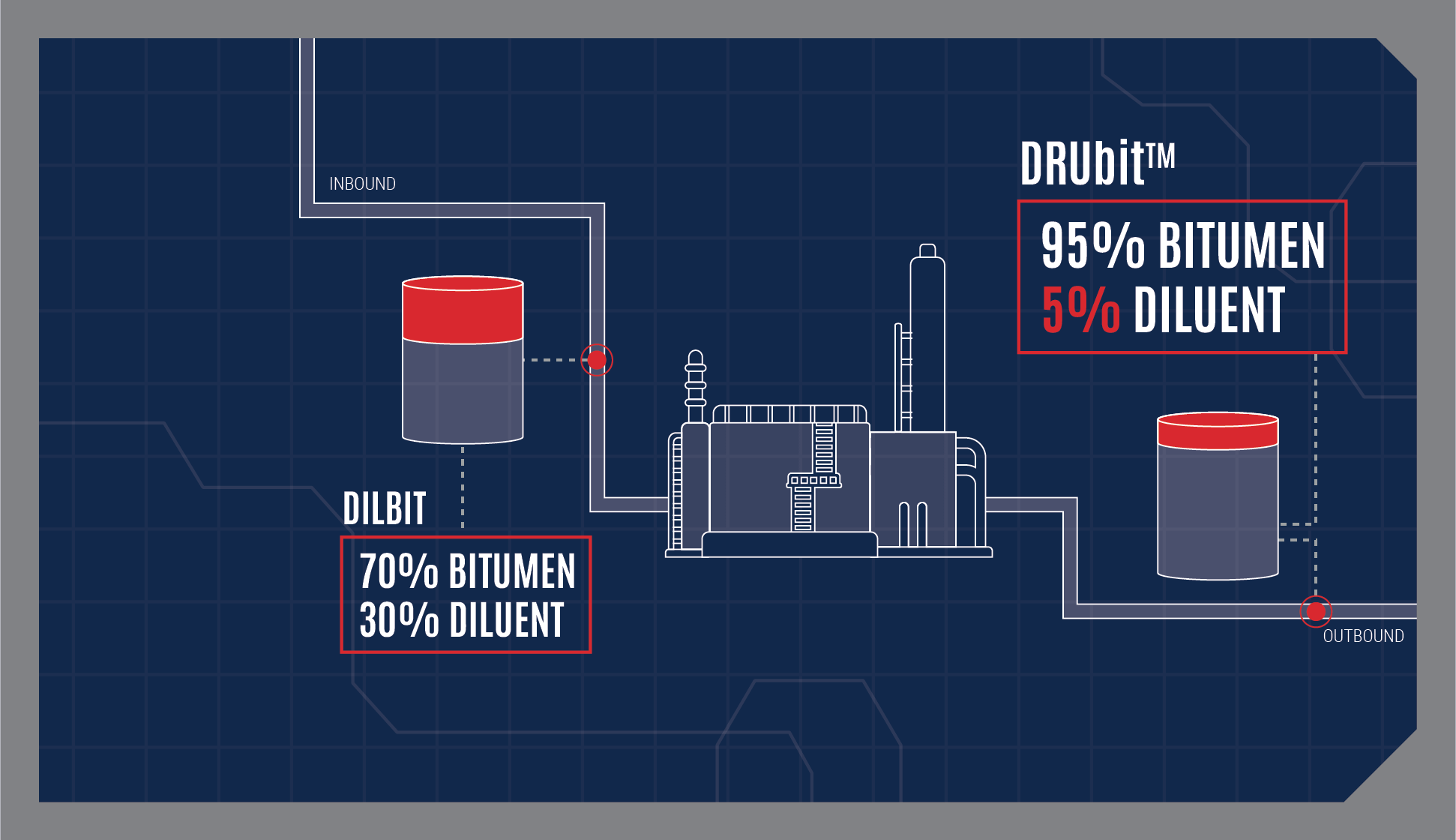

Patented by USDG, DRUbitTM is a non-hazardous, non-flammable commodity that improves safety and enables more direct transportation routes to refineries. By extracting the light diluent componenet from dilbit (70% bitumen) that is added to facilitate pipeline transportation, the resulting DRUbitTM is a heavier product (95% bitumen) with increased bitumen concentration that can be shipped by rail.

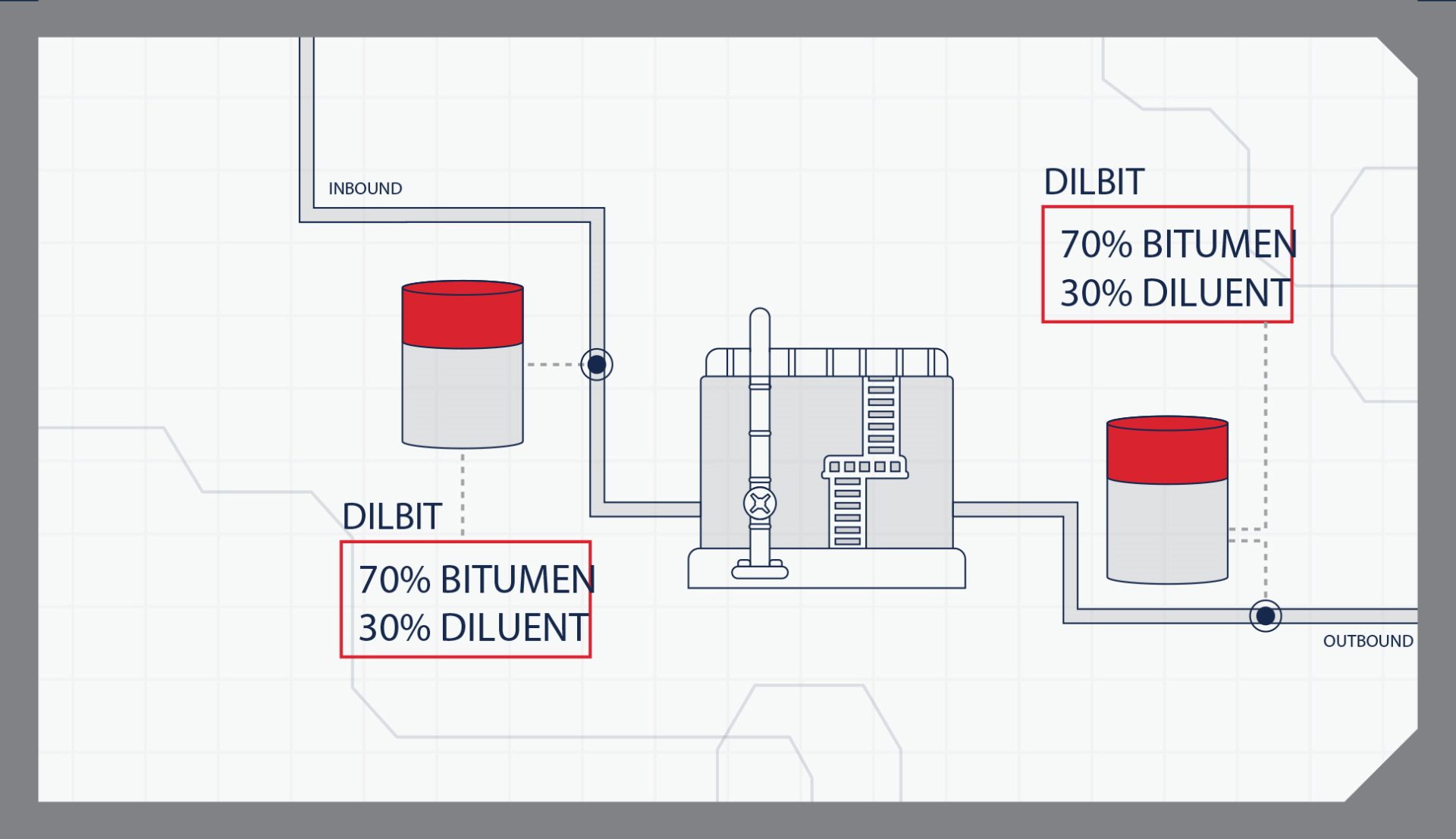

from

70% Bitumen

30% diluent

to

95% Bitumen

5% diluent